- Home

- RFID Manufacturing

Kingloo is located at located at entry of Shanghai–Jiaxing–Huzhou Expressway to Shanghai Outer Ring Expressway in Pudong New Area Shanghai, which is connected to S20 highway. It only takes 10 minutes to drive car from company to Pudong international airport and takes only 40 minutes to drive from company to Yangshan deepwater port, which means the convenient transportation will save delivery cost for you.

Raw Material

The label is very small, but its each component is very important, the raw material it use will determine the performance of products, therefore we get very attached to material choosing to meet clients’ requirements.

Specifically, the core part of RFID label is chip, we choose the three international famous chip manufacturers to cooperate, which are NXP, Impinj,Alien, and we choose the international famous binding factories to manufacture dry inlay, which are Yongdao, Arizon, Shangyang, Lianhengwuyu separately.

the film covering the label surface adopts the products from Aili and UPM, for the glue we adopt the double sided tape from 3M company and hot melt glue from Hangao company to have good stickiness

Our company is located at Shanghai with abundant industrial resources. We could complete above material purchasing inside Shanghai, which could save huge unnecessary transportation costs, therefore we could provide cheaper products with the same good quality.

Production

Kingloo has rich experience of more than 10 years manufacturing binding machine and lamination machine, and have deep understand in RFID labels production technology, which make manufacture RFID labels flexibly and efficiently, there are three steps in production

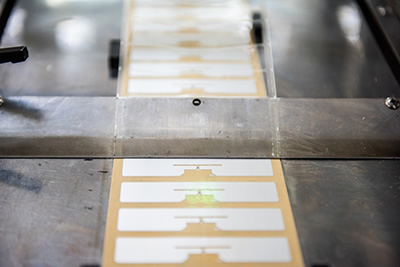

1. lamination

In this step, we need to adhere the paper film to the dry inlay by glue to make a integral label, the lamination machine is developed by ourselves, so we are familiar with each component in this machine to make it manufacture labels flexibly

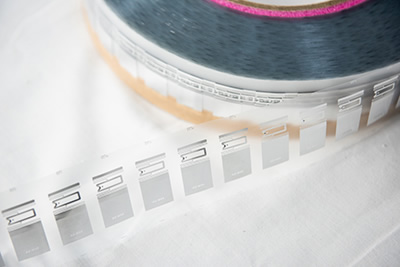

dry inlay

dry inlay wet inlay

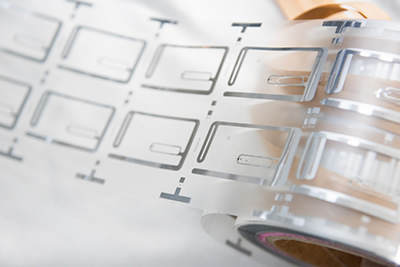

wet inlay RFID label covered with paper film

RFID label covered with paper film

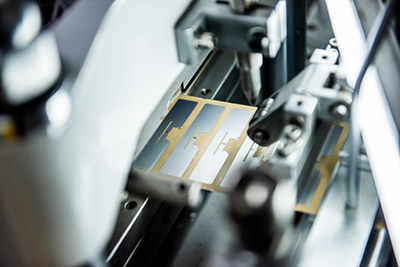

2. Die cutting

We have two high precision die-cutting machine of different specification, which is customized to match lamination machine.the die-cutting machine and lamination machine is combined as an production line, therefore the compatibility is good between lamination machine and die-cutting machine to manufacture different types of labels

3.ExamineWe use the professional ecoding and print personalizational machine to carry full test on RFID labels, which could make sure the inner data, performance and appearance will meet all requirements of our clients.

There are four working pattern:- examine pattern

- Examine the TID and EPC code in the UHF labels

- Examine UID code in the HF labels

- Make sure the performance of each label is perfect

- Code pattern

- Scan the bar code printed on the labels and write the information into labels

- Import database and write it into labels

- Code plus print

- Import database, print bar codes and write them into labels

- Code plus print plus examine

- Import database, print bar codes and write them into labels. Then scan the bar code printed on the labels and check the information

- Import database, print bar codes and write them into labels. Then import EPC database, check the RFID labels information based on EPS database

- Import database, print bar codes and write them into labels. Then scan the bar code printed on the labels and check the information; finally import EPC database, check the RFID labels information again based on EPS database

Shanghai Kingloo Technology Co., Ltd.

Add: 3rd floor of Building No.7,No.139 Xuanqiu Road, Sanzao Industrial Park, Pudong, Shanghai

Contact Person: Mr. Johnson

Telephone: +86-21-20980826

Fax: +86 21- 20980032