- Home

- Industries

- Inventory Management

The traditional inventory management was operated with manual sign-in and sign-out. Operators commonly recorded inventory data by a paper file and traditional barcode label. The entire management process was tedious and inefficient, causing a waste of time and resources.

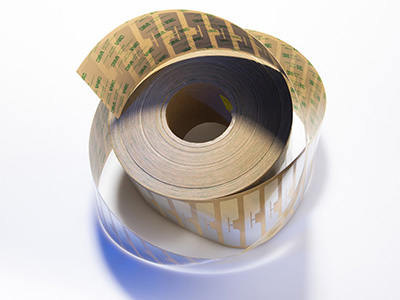

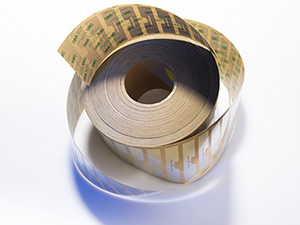

However, unlike the former inventory management method, our UHF RFID tags are able to provide more intelligent inventory management for your business.

These RFID electronic tags are attached to pallets and related storage locations. Meanwhile, RFID readers are mounted on trucks or forklifts. Mounted readers automatically read the tags to collect the item data and send them to the database host, brining convenience to almost every sector of a warehouse, such as receiving, put-away, picking, packing, and delivery. You also can monitor the identity, state, or location of every tagged product, and get the related report.

In this inventory management process, there is no extra manual operation involved. The RFID technology automates the whole management process with dramatic labor cost reductions. Any inappropriate delivery will be detected automatically and timely by our smart system. It can improve the inventory accuracy and decrease out of stock rate by 12%.

Shanghai Kingloo Technology Co., Ltd.

Add: 3rd floor of Building No.7,No.139 Xuanqiu Road, Sanzao Industrial Park, Pudong, Shanghai

Contact Person: Mr. Johnson

Telephone: +86-21-20980826

Fax: +86 21- 20980032